DUAL FUNCTION ICE & ICE WATER PLANT

Key Facts

- Ice output: 100 tons of ice/day (assuming existing cold water at maximum 1°C -> 3°C water temperature)

- Ice production: "just-in-time"

- Ice water production: nominal 244 m./day (assuming existing fresh water at 45 °C)

- Faster assembly and disassembly as a result of the modular container construction of the ice & cold water system and the ice store

- "FIFO" First-in, first-out ice store: up to 60 tons possible

- Guaranteed 30-50 % energy savings vis-à-vis conventional ice systems due to a higher refrigerant temperature of only -10 °C instead of -28 °C as well as the smart storage design

- Ice store and ice machine do not require an additional cooling unit which adds to the efficiency

- Ice and ice water production possible using the same system

- Combination of up to 4 ice machines permits 400 tons of ice/day over single storage system

- No glaciation and easy ice transport as a result of the unique screw shelf

- Very low maintenance as there are no moving wear parts on the ice production unit

- Ice transport via screw conveyors with an incline of 45° and a distance of up to 60 m possible

- Ice weighers with optimised + controlled ice discharge

Capacities Available

Single unit 100 tpd ice production or multiple installations 200, 300 or 400 tpd.

Please see the above diagrams illustrating some of the variations available for the set up of your EUROKOOL plant. For alternative configurations, specific requirements or any questions please don’t hesitate to contact our technical support.

GENERAL SPECIFICATIONS

| Designed for 24-hour operation | |

| Wet-bulb temperature for power information | 29,5 °C |

| Condensation temperature | 42 °C |

| Operation with refrigerant | NH³ (R717) |

ELECTRICAL CONNECTION

| Connection power PNom | 165 kW |

| Amperage INom | 240 A |

WATER CONNECTIONS

| Required water pressure at the water inlet | 2-4 bar |

| (warm/or cold) water inlet ice/cold water unit | 4“ connection |

| Cold water outlet | 4“ connection |

| De-sludge water condensation liquefier | connection |

40‘ HIGH CUBE CONTAINER PARTLY INSULATED DIMENSION AND COLOR

| Length | 12.192 mm |

| Width | 2.438 mm |

| Height | 2.896 mm |

| Body paint color | RAL 7035 |

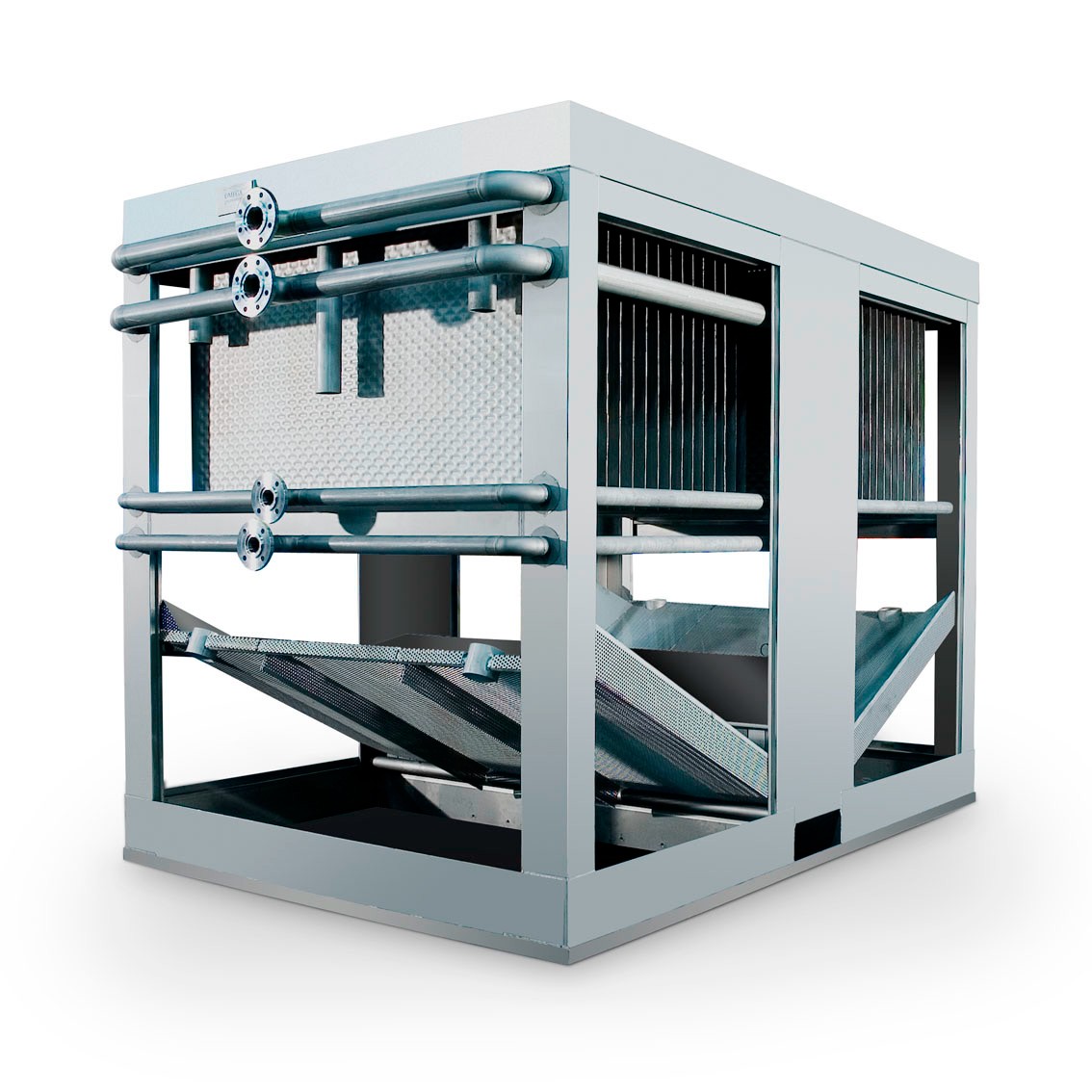

EUROKOOL ICE & ICE WATER UNIT

| Cooling surface | 154 m² |

| Evaporator material | 1.4404 stainless steel |

| Maximum permissible operating pressure (refrigeration cycle) | 17 bar |

| Number of evaporator plates | 38 items |

| Evaporator content | approx. 324L |

| Ice type | platelet ice |

| Ice thickness | 5-9 mm |

| Maximum ice production | 4.16 tph (100tpd) |

| Ice temperature | - 5 to – 1 °C |

| Maximum ice water production | 15m3/hr (360m3/day) |

| Minimum ice water production | 10.2m³/hr (244m³/d) |

| Water outlet temperature | 0.5 to 2 °C |

| Maximum water inlet temperature for given cold water performance | 45 °C |

- Maintenance-free downdraft plate evaporator

- Open construction

- Optimised for container operation

- Split cooling structure, i.e. plate groups can be controlled separately

- Can be switched over from ice production to ice water operation and vice-versa at any time

- Evaporator plates in accordance with PED 97/23/CE

- Split design for increased operating safety

- Including 1 water circulating pump, 1 mechanical float valve, 1 frequency-controlled centrifugal pump for cold water production

- Ice water production can be continuously adjusted to the water inlet temperature using a controlled centrifugal pump

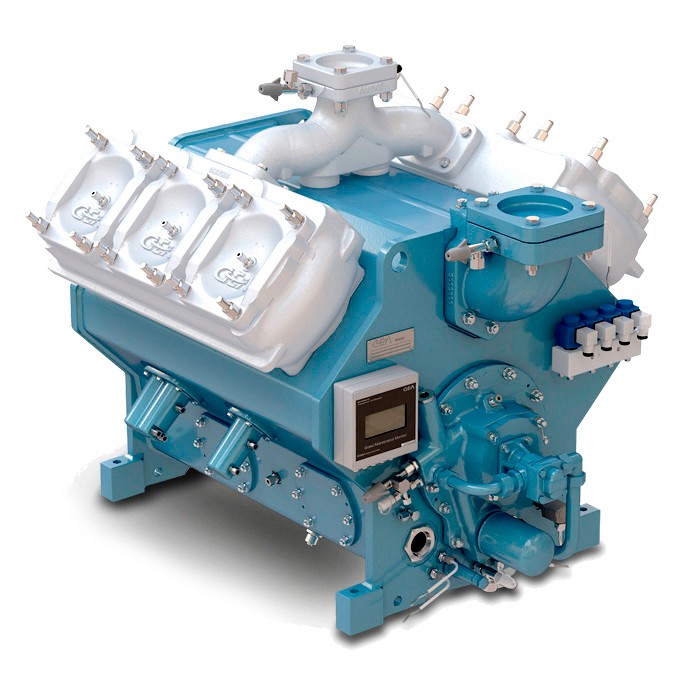

AIR-COOLED GRASSO RECIPROCATING

PISTON COMPRESSOR V1100

| Number of cylinders | 6 |

| Drive type | power belt |

| Drive with electric motor 400 V / 50 Hz / 3 Ph. | 200 kW |

| Electric motor power consumption | 155 kW |

| Evaporation temperature (cold water generation) | approx. -3 °C |

| Evaporation temperature (ice production) | approx. -10 °C |

| Compressor speed | 965 rpm |

- Low maintenance, including oil separator, cylinder head temperature monitoring

OPTIMIZED BAC CONDENSATION LIQUEFIER

Exclusive EUROKOOL-Models with four axial ventilators

| Model | 2x BAC VXC97 or equivalent Special models |

| Cooling type | water cooling |

| Capacitor nominal power | 870 kW |

| Air volume | 14.2 m³/s |

| Spray water volume | 14.2 L/s |

| Ventilator drive with electric motor 400 V / 50 Hz / 3 Ph. | 2x 1.2 kW |

| Pump drive with electric motor 400 V / 50 Hz / 3 Ph. | 2x 0.75 kW |

- Housing made from zinc-plated sheet steel

- All zinc-plated sheet metal parts come with additional corrosion protection on PVC/acrylic resin basis

- Axial ventilators directly driven by three-phase AC motor in accordance with IEC standard

- Including run dry protection

- All screw connections are made from stainless steel

OINSULATED WITT HAM 660X2330 NH³ LIQUID SEPARATOR

2-components epoxy resin coating on the exterior; including maximum level limiter and visual level status display

| Operating pressure of 17 bar within the temperature range | -10 / 50° C |

| Designed for cold performance (cold water generation) | 580 kW |

| Designed for cold performance (ice production) | 400 kW |

HRP 5040 HERMETIC REFRIGERANT PUMP

| Transport capacity | ca. 7.2 m³/h |

| Pump drive with electric motor 400 V / 50 Hz / 3 Ph. | 2.2 kW |

GFG GMA44 NH³ GAS DETECTOR

| Including 2 NH³ sensors; with external malfunction signal, completely wired and pre-assembled |

2 HR2-SK-H HIGH-PRESSURE FLOAT REGULATORS

| Including ventilation system; shut-off values at inlet, outlet and for emptying | |

| Designed for cold performance (cold water generation) | 275 kW |

| Designed for cold performance (ice production) | 200kW |

AUTOMATICALLY-VENTILATED ELECTRICAL CONTROL CABINET WITH SIEMENS SIMATIC TIA PROGRAMMABLE LOGIC CONTROLLER

- Including Software Ice Plant Visio 5.05

- Including USP with condenser; making changing batteries a thing of the past

- Operation using a Siemens Simatic Multi Panel

- Including frequency converter for the evaporator’s circulating pump

- Including frequency converter for cold water pump

- Optional

- Remote diagnosis image in the concrete unit - External status lamps: operation, malfunction, store fill level

ICE WEIGHER TYPE EW0350-01

Zinc-plated ice weigher with electrical metering facility

| Model | 2x BAC VXC97 or equivalent Special models |

| Cooling type | water cooling |

| Capacitor nominal power | 870 kW |

| Air volume | 14.2 m³/s |

| Spray water volume | 14.2 L/s |

| Ventilator drive with electric motor 400 V / 50 Hz / 3 Ph. | 2x 1.2 kW |

| Pump drive with electric motor 400 V / 50 Hz / 3 Ph. | 2x 0.75 kW |

| Width | 1.250 mm |

| Height | 2.350 mm |

| Depth | 1.100 mm |

| Suitable conveyor belt width | from 800 mm |

| Discharge system | internal development (similar to the cellular wheel sluice) |

| Metering time (discharge time) | ca. 15 s at 300 kg |

| Drive motor rating 400 V / 50 Hz / 3 Ph. | 1.5 kW |

- Secured uniformity using gear wheels

- Slide bar lock using integrated proximity switch

- Including inspection flap

- Other weight class

FULLY-INSULATED 3 PART 40‘ HIGH CUBE ICE STORE INCLUDING TYPE 4 X 476 SCREW OUTLET SHELF

EXTERNAL MEASUREMENTS

| Length | 12.192 mm |

| Width | 2.438 mm |

| Total height including twist locks | 8738 mm |

| Room volume | 138 m³ |

| Capacity | 60 tons |

| Number of screw conveyors | 4 |

| Screw conveyor spiral | Ø 476 mm |

| Screw conveyor spiral material | ST 37 |

| Total transport capacity | approx. 30 tons/h |

| Number of gear motors | 4 |

| Gear motor rating 400 V / 50 Hz / 3 Ph. | 4 kW |

| Output speed | 4.5 rpm |

- Siemens Simatic TIA logic control

- Including inspection flap

- Integrated defrosting water outlet

EUROKOOL ICE & ICE WATER UNIT

| Number of screws | 1 |

| Screw spiral Ø | 300 mm |

| Screw spiral material | ST 37 |

| Total transport capacity | ca. 30 t/h |

| Number of gear motors | 1 |

| Gear motor rating 400 V / 50 Hz / 3 Ph. | 4.0 kW |

- Split design for faster onsite assembly

- 2 screw outlets for feeding 2 inclined screws – optional

ICE SCREW CONVEYORS

| Maximum incline | 45° |

| Maximum length | 60 m |

- Flexible configuration

- Integrated defrosting water outlet

- Fully-insulated